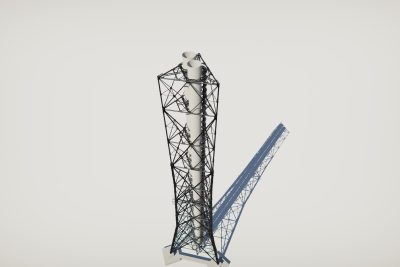

Beyond our foundational offerings, we take great pride in presenting our esteemed consulting and supervision services, ensuring our clients bask in tranquility concerning project quality and timelines. In this article, we shall explore the pivotal stages of our consulting and supervision process throughout production.

1. Incoming Material Inspection: Prior to starting any project, it is essential to conduct a comprehensive inspection of all materials. Our engineering team carefully evaluates every component and material to ensure they meet the highest quality standards. This proactive measure not only avoids expensive delays but also ensures that the final product fulfills both technical and aesthetic criteria. By following international standards and industry safety regulations, we offer our clients unmatched confidence.

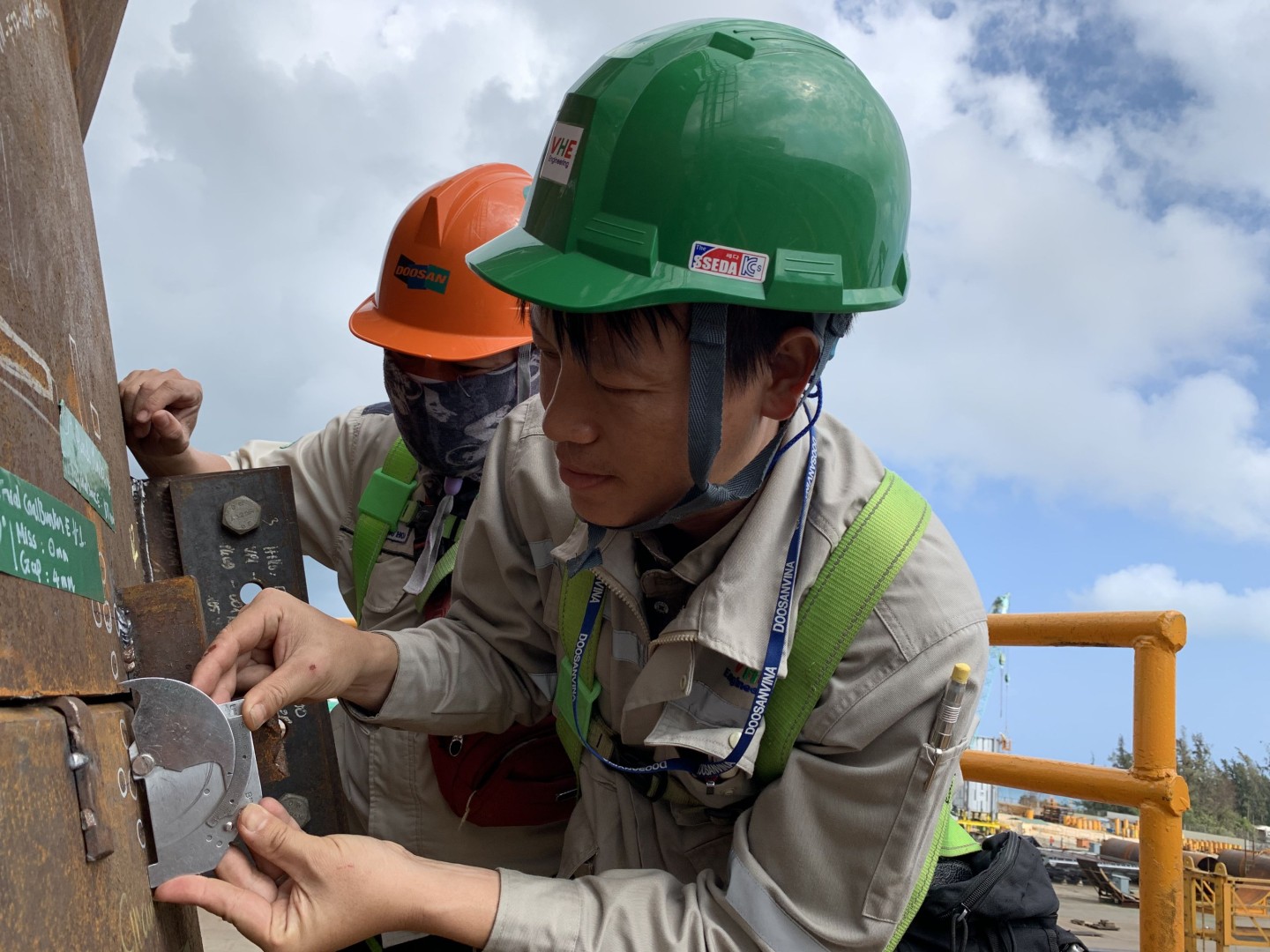

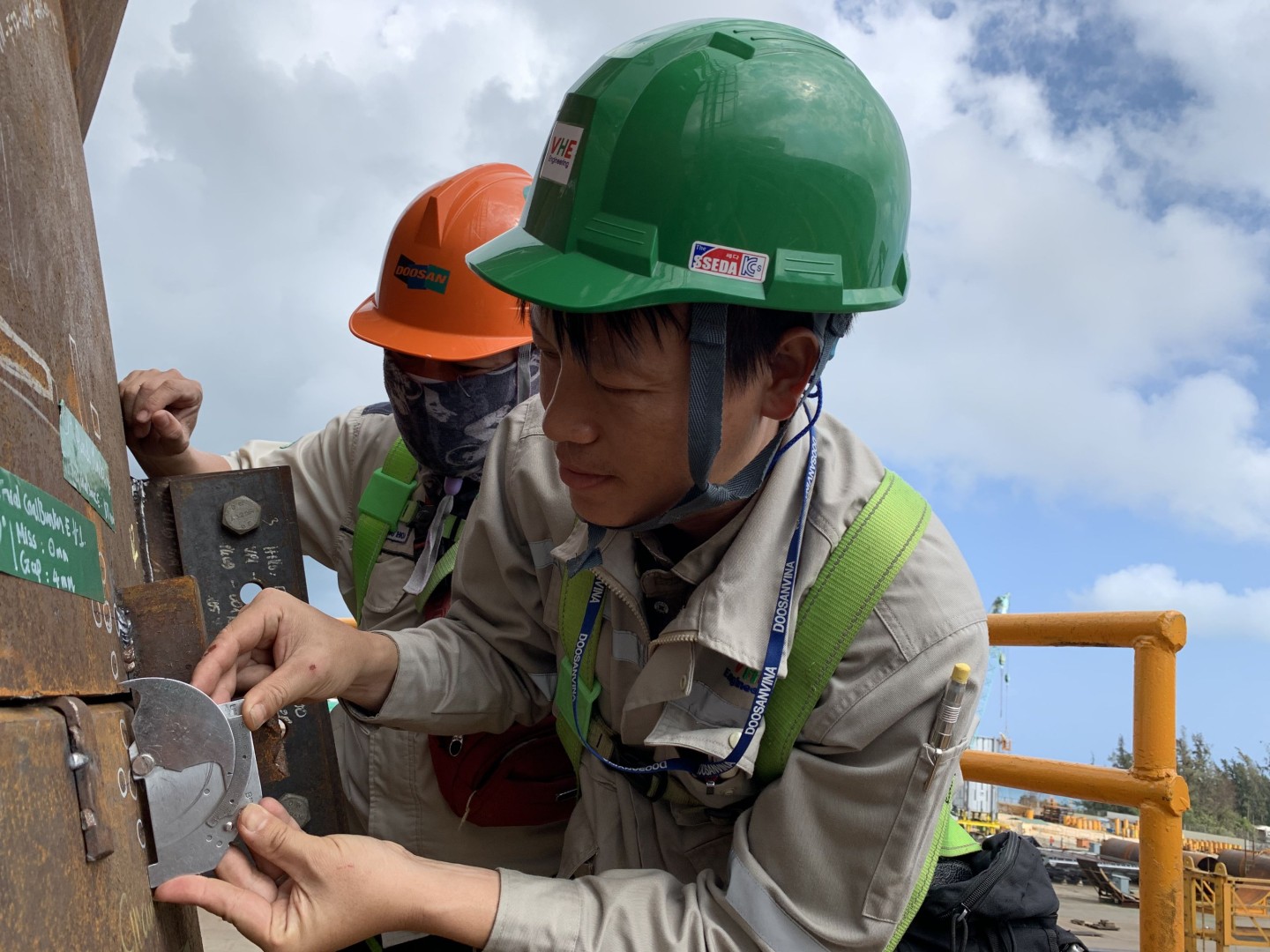

2. Marking, Fitting, and Inspection: After inspecting the materials, we move on to the marking, fitting, and inspection stage. This step is vital for maintaining accuracy and uniformity throughout the manufacturing process. Our engineers utilize state-of-the-art tools to precisely measure and position each component. By detecting and resolving any inconsistencies at this stage, we improve product quality and speed up the construction timeline.

3. Welding Inspection: Welding is an intricate and skilled craft. Our supervisory team performs thorough welding inspections to ensure that every weld adheres to strict technical standards, guaranteeing the durability and safety of the final product.

4. Post-Painting Inspection: After the welding process is finished, the product is treated with a protective coating. We conduct a thorough inspection of the paint quality to ensure that it is both visually striking and durable enough to endure different environmental challenges, including weather, chemicals, and abrasion. By adhering to strict standards for adhesion, thickness, and gloss, we ensure the product’s superiority.

5. Product and Process Documentation Review: To ensure transparency and precision, VHE performs thorough evaluations of both product and process documentation. This documentation covers every facet of the project, from raw materials to manufacturing techniques. In addition to acting as a final quality assurance step, this review offers clients complete insight into the production process, enhancing trust and professionalism.

6. Finalization of the Completion Document: In the end, VHE assembles a thorough completion document that encompasses all materials related to the project. This document aids in efficient project tracking and acts as a basis for future maintenance and product utilization. It features inspection reports, invoices, quality certificates, and instructions for product use. This approach not only improves client convenience but also highlights VHE’s dedication to quality and service.