VHE’s Vision – Prepared for the Bright Future

A robust vision is essential for VHE’s continuous development over its 16-year journey. Vision is a critical component not only in business but also a key determinant of success...

View moreI. Flare System Types:

Flare systems are classified into two main types based on their installation location (Whatispipping.com):

Vertical Flare System Types:

VHE specializes in designing, fabricating, and installing self-supporting flare systems. With extensive experience in all three horizontal flare system types, we offer comprehensive solutions that meet your specific requirements.

Horizontal Flare System Type:

Horizontal flare systems are installed horizontally, with waste gases directed through a pipe to a horizontal burner. The gases are then discharged into a pit or trench. Horizontal flare systems are typically used in areas with limited space or where noise and thermal radiation need to be minimized.

II. Applications of Flare System Types:

Flare systems are widely used in various industries for the safe and efficient treatment of waste gases. Some of the most common applications include:

1. Industrial Waste Gas Treatment:

Flare systems are employed to handle waste gases generated from industrial plants, including chemical plants, refineries, paper mills, power plants, and more. These waste gases often contain hazardous and harmful substances, such as VOCs (volatile organic compounds), SOx (sulfur oxides), NOx (nitrogen oxides), CO (carbon monoxide), and others. Flare systems combust these pollutants at high temperatures, converting them into harmless CO2 and H2O.

2. Oil and Gas Waste Gas Treatment:

Flare systems play a crucial role in treating waste gases from oil and gas operations, including produced gas, wellbore gas, flare gas, and others. These waste gases typically contain flammable components, such as methane, ethane, propane, butane, and more. Flare systems safely incinerate these flammable components, preventing fire and explosion hazards while protecting the environment.

3. Municipal Waste Gas Treatment:

Flare systems effectively handle waste gases generated from wastewater treatment plants and landfills. These gases often contain harmful substances like methane, hydrogen sulfide, ammonia, and others. Flare systems combust these pollutants to minimize air pollution and protect public health.

4. Other Industrial Applications:

Flare systems find use in treating waste gases from various industries, including:

A robust vision is essential for VHE’s continuous development over its 16-year journey. Vision is a critical component not only in business but also a key determinant of success...

View more

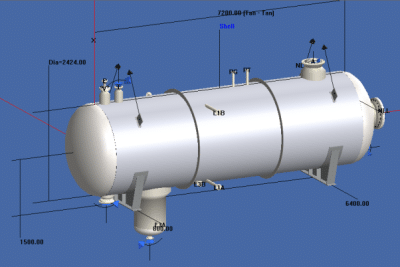

Pressure equipment is essential in a range of industries such as chemical, oil and gas, power generation, food and beverage, pharmaceuticals, and others. These vessels are crafted to handle,...

View more

After 16 years of establishment and continuous development, Viet Han Engineering Co., Ltd. has achieved significant milestones within the industry. Let us delve into VHE’s noteworthy accomplishments: Viet Han...

View more

Flare system holds a pivotal position within the manufacturing industry. Delve into an in-depth exploration of its structure and operating principles in VHE‘s article. I. Definition: In mining rigs,...

View more

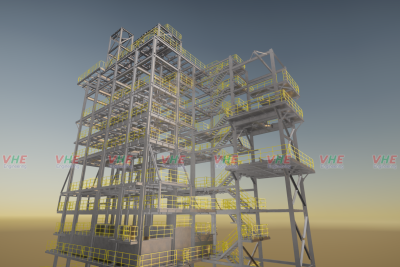

Steel structure is currently recognized as a promising solution that aligns with various sustainability standards in construction. The forthcoming article will delve deeper into its significance and diverse applications....

View more

QA/QC System (Quality Assurance/Quality Control) is pivotal in safeguarding product quality and enhancing customer satisfaction. This system serves to boost production efficiency while guaranteeing adherence to global quality benchmarks....

View more

Reducing risks in manufacturing management is crucial for fostering sustainable business growth. In the manufacturing sector, various threats can impact business processes and employees. VHE focuses on enhancing safety...

View more

Inventor is a powerful 3D design (CAD) tool widely used in various mechanical engineering fields. With its detailed modeling, thorough analysis, and automation capabilities, Inventor offers numerous benefits to...

View more

Tekla Structures is a leading Building Information Modeling (BIM) software widely used in the field of steel structure design. It provides engineers and designers with powerful tools to create...

View more

Steel has historically symbolized the evolution of the modern construction sector. Its exceptional characteristics such as durability, high load-bearing capacity, and flexibility play a vital role in constructing both...

View more

We will contact you upon receipt of the information