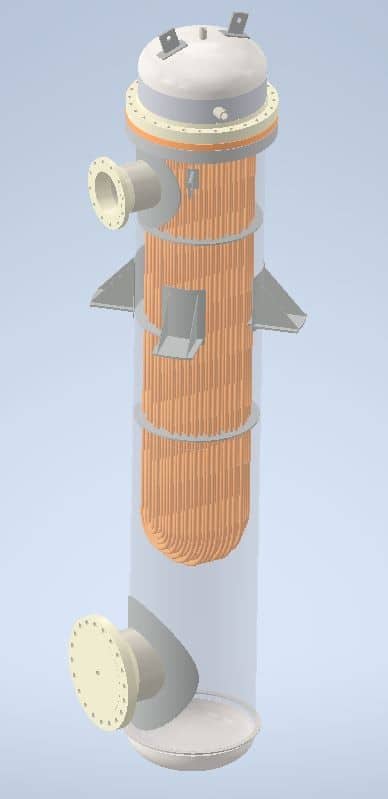

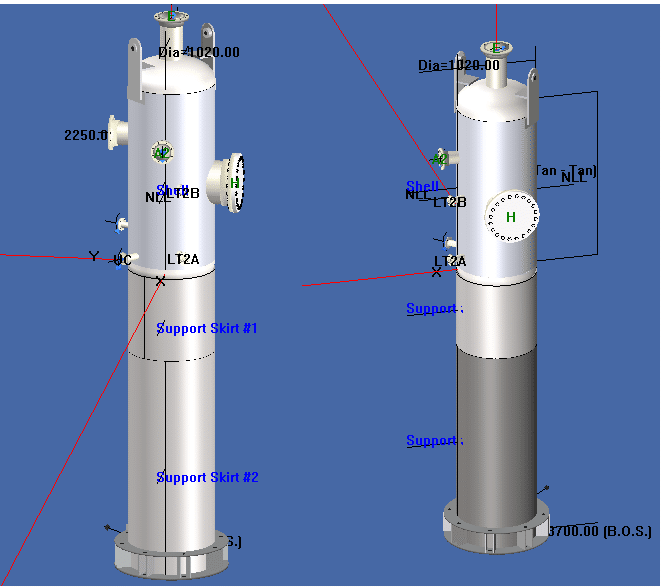

Pressure vessels play a crucial role in both modern industrial production and our everyday lives. Whether it’s the pressure cookers in our kitchens or the large-scale boilers in factories, they are omnipresent. Despite their prevalence, many fail to recognize the potential hazards these devices pose when mishandled. How can we guarantee safety when dealing with pressure vessels? See more in the article.

Regardless of their size, pressure vessels pose considerable risks if not operated and maintained correctly. One of the most critical dangers is the potential for explosion or rupture. Exceeding the designed pressure limits can lead to severe explosions, building collapses, worker injuries, and significant property damage. Another major concern is the leakage of hazardous substances. The liquids or compressed gases within the vessel could include toxic or flammable chemicals. If a leak occurs, it can result in environmental contamination, endanger human health, and potentially lead to fires or explosions.

Factors Contributing to Accidents:

Accidents involving pressure vessels can have severe consequences, resulting in both human and property damage. Several factors contribute to these unfortunate incidents:

Design and manufacturing errors are significant contributors. The use of substandard materials, non-compliant designs, or designs not suitable for actual operating conditions can make equipment vulnerable to damage, leaks, or ruptures.

Operating errors are another common cause. Operating equipment beyond its limits, not following safe operating procedures, or lack of operator experience can all lead to serious incidents. The pressure vessel’s operating environment, including high temperatures, humidity, noise, or toxic conditions, can impact the operator’s health and focus, increasing the likelihood of errors.

Additionally, inadequate or irregular maintenance can be a potential cause. Corrosion, wear and tear, or hidden defects may go unnoticed and unrepaired, resulting in unfortunate outcomes.

Lastly, the human factor is crucial. Operator complacency, negligence, or inadequate training can lead to significant errors.

Preventive Measures:

To guarantee the safe utilization of pressure vessels, it is essential to put the following preventive measures into practice:

- Regular inspection: Conduct routine technical inspections to detect and promptly rectify any damages.

- Maintenance: Follow the maintenance schedule recommended by the manufacturer.

- Proper operation: Thoroughly review the operating instructions and adhere to all procedures.

- Personal protective equipment: Utilize suitable personal protective gear like gloves, safety glasses, and protective clothing.

- Safe working conditions: Maintain a clean, well-ventilated, and well-lit work environment.

- Training: Arrange safety training sessions for operators.

Emergency Response:

In the event of a pressure vessel incident, a prompt and precise response is essential. Here are some immediate response steps to take:

Warning: Notify all individuals nearby and inform emergency services.

Evacuation: Remove people and assets from the hazardous area.

Power and fuel shutdown: Stop the power and fuel sources to contain the incident.

Firefighting equipment: Utilize suitable firefighting gear in case of a fire or explosion.

Seek emergency help: Get in touch with trained emergency services for assistance.

Conclusion:

Pressure vessels play a crucial role in manufacturing and everyday activities, yet they come with substantial risks if mishandled. To guarantee safety, it’s essential to conduct regular equipment inspections and maintenance, follow operational procedures, wear appropriate personal protective gear, be ready for emergencies, and undergo proper training. By complying with safety protocols, not only do we safeguard ourselves and our peers, but we also enhance production stability and minimize financial losses.