Our tanks go beyond mere equipment; they represent the ideal solution for improving production efficiency while safeguarding the environment. Featuring exceptional quality, extended durability, and adaptable customization options, tanks manufactured by VHE assist customers in lowering operational expenses, ensuring safety, and adhering to the highest standards.

1. Common Types and Their Applications:

With diverse shapes, sizes, and materials, tanks cater to the storage needs of various industries, from chemicals and gas to food.

- Chemical Storage Tanks: They are specifically engineered to safely contain highly corrosive substances, including acids, bases, salts, and solvents. To ensure both safety and the integrity of the chemicals stored, these tanks are typically constructed from materials that exhibit exceptional corrosion resistance, such as stainless steel and composites. With their robust heat and pressure resistance, chemical storage tanks are vital components in chemical and pharmaceutical manufacturing facilities, facilitating continuous and secure production processes.

- Coned Roof – Dome Roof Tanks: These are engineered with an efficient rainwater drainage system that alleviates pressure on the tank walls, thereby enhancing the structure’s longevity. This specialized design allows for the safe storage of clean water, wastewater, chemicals, and oils in factories, plants, and industrial areas. In addition to their protective capabilities, the sloped design contributes to the aesthetic appeal of the structure.

- Liquefied Natural Gas (LNG) Storage Tanks: Liquefied natural gas (LNG) is produced by cooling natural gas to extremely low temperatures, transforming it into a liquid state that simplifies transportation and storage. Consequently, LNG storage tanks are designed to endure both low pressure and temperature conditions. Typically constructed from stainless steel or aluminum alloys, these tanks feature advanced insulation to preserve the low internal temperatures necessary for LNG. They are commonly utilized in gas production facilities and pumping stations for the storage of natural gas and petroleum gas.

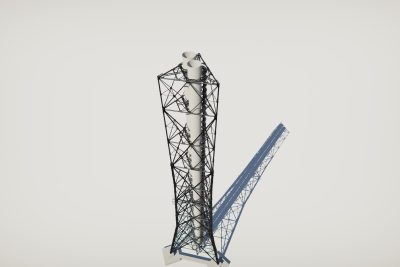

- Spherical Storage Tanks: Spherical storage tanks are engineered with a perfect spherical design, maximizing storage capacity while effectively withstanding high pressure. Their symmetrical structure allows for even distribution of force across the entire surface, minimizing the risk of deformation and leakage. These tanks are commonly utilized for the storage of natural gas, liquefied gases, and various industrial gases.

2. Manufacturing Process

Our tank manufacturing process commences with a thorough design phase. Utilizing customer-provided specifications related to capacity, material, operating pressure, and environmental conditions, we carefully delineate the exact requirements. Leveraging this information, our VHE engineering team selects the most appropriate materials, ensuring that all technical parameters are accurately calculated and implemented.

Following the design stage, the manufacturing process begins. Various materials and components are precisely cut and welded to create the tank’s structure. Simultaneously, auxiliary components, such as pipelines and valves, are fabricated to complete the assembly.

Once the components are fully assembled, we conduct rigorous quality checks to verify the integrity of all welds and the overall tightness of the tank. This step is critical to ensuring the safety and quality of the final product.

Subsequently, the tanks undergo comprehensive testing to assess their pressure resistance and leak-proof capabilities. This meticulous testing process allows us to identify and rectify any potential defects or weaknesses.

Finally, the completed products are coated with a protective layer to enhance durability and corrosion resistance, ensuring they are ready for immediate use and adhere to the highest quality standards.

3. Conclusion:

From the initial design phase to the final product, every stage of our manufacturing process is executed with the utmost care and precision. We recognize that our tanks are not merely products; they are essential components of our customers’ production processes. Therefore, we are dedicated to delivering high-quality solutions that meet even the most stringent requirements.