VHE’s Vision – Prepared for the Bright Future

A robust vision is essential for VHE’s continuous development over its 16-year journey. Vision is a critical component not only in business but also a key determinant of success...

View more

Creating and building a flare system is a challenging task that requires in-depth knowledge and practical experience from seasoned professionals in the industry. An imperfect design can lead to serious consequences. In this article, we will guide you through the crucial factors to consider when developing a flare system, covering both technical details and our expert working approach.

Journey and reflections in the creation.

When embarking on the design of a flare system, it is essential to approach the workflow with a systematic and professional mindset. This commitment guarantees that every relevant factor is thoughtfully taken into account.

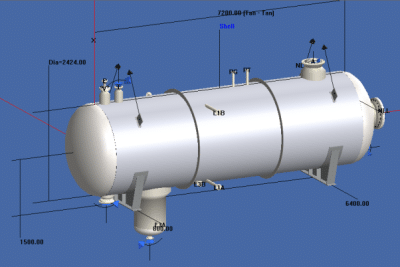

First, it is essential to clearly outline the requirements for the flare stack system. This involves evaluating the volume and type of exhaust gas that needs treatment, as well as the safety and environmental standards that the system must adhere to. Key specifications, including pressure, temperature, and chemical composition of the exhaust gas, must be documented to provide a foundation for the subsequent design phases.

Risk analysis stands as a vital cornerstone in uncovering potential hazards linked to the design and operation of the combustion tower. This process encompasses evaluating scenarios that may result in fire, explosion, or environmental pollution. By employing both quantitative and qualitative analysis methods, we can forge robust risk control measures that pave the way for safety and resilience.

Design Process:

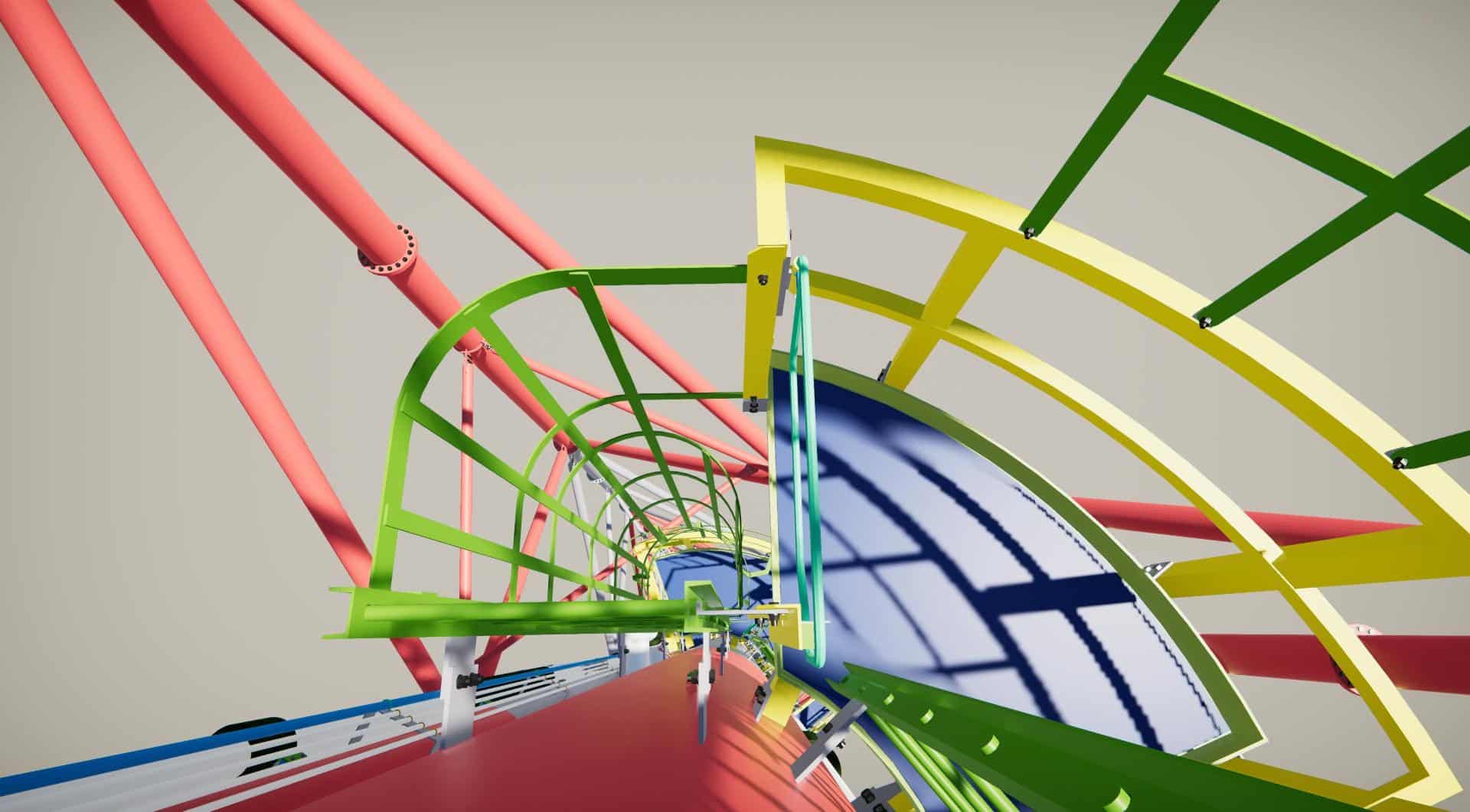

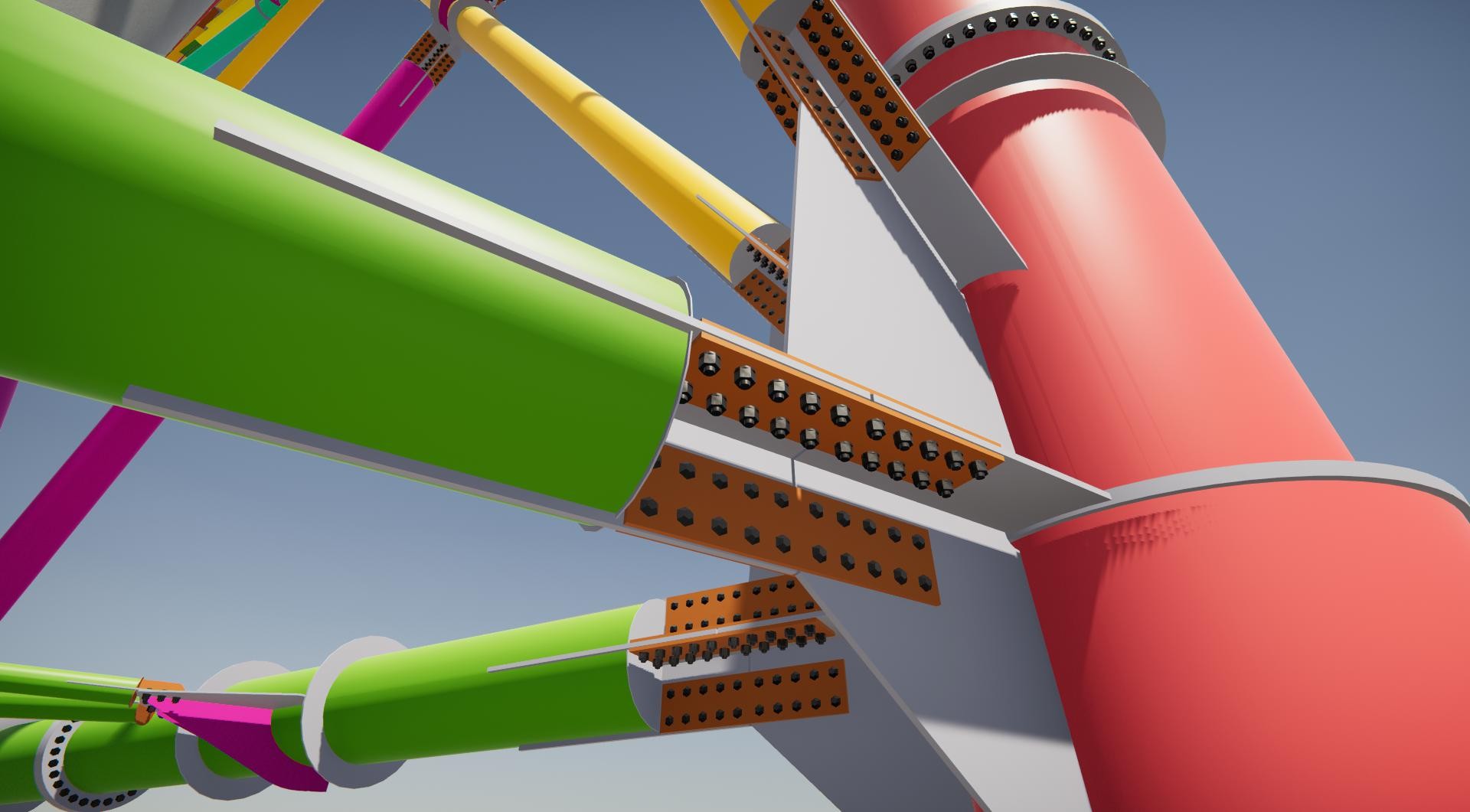

In alignment with the established parameters and requirements, a comprehensive design for the combustion tower will be undertaken. This process encompasses the careful selection of materials, dimensions, shape, and structure of the tower. It is essential to guarantee that the design not only fulfills the technical specifications but also adheres to international standards for pressure equipment and safety, thereby minimizing toxic emissions and environmental impacts. Advanced software will be employed to create 3D simulations and assess the system’s performance prior to the construction.

Installation:

Before construction, it is essential to simulate the flare system to evaluate its effectiveness in treating exhaust gas. Utilizing specialized simulation software will enable the prediction of the tower’s behavior under various operating conditions. Concurrently, conduct tests to guarantee that the design adheres to all safety and performance standards.

Once the design and testing phase reaches its conclusion, we embark on the vital journey of constructing and installing the combustion tower. It is essential that this process is undertaken by a skilled team of engineers and workers, diligently adhering to labor safety regulations. Vigilant oversight of the installation is crucial to guarantee that every component is assembled with precision and aligns with the highest standards.

Notes on the Design Process:

While designing and constructing the flare system, several critical points require careful consideration. The foremost aspect is compliance with legal regulations, making certain that both the design and operation of the system adhere to all safety and environmental protection standards set by the relevant authorities.

Moreover, selecting the appropriate materials holds immense significance. Opting for heat-resistant, corrosion-resistant, and durable materials will greatly contribute to the longevity of the combustion tower. Furthermore, it is essential to consider environmental factors; the design must thoughtfully address the effects on the surrounding environment, including the management of noise and odors generated by the combustion process.

Ultimately, embracing the ever-evolving landscape of technology is crucial. Staying informed about the latest advancements in the flue gas treatment and combustion tower sector will enhance both performance and safety. By adhering to a meticulous design process and focusing on vital elements, you will create a flare stack system that embodies efficiency, safety, and environmental stewardship.

A robust vision is essential for VHE’s continuous development over its 16-year journey. Vision is a critical component not only in business but also a key determinant of success...

View more

Piping systems become a vital component of contemporary life. Ranging from small civil projects to large-scale industrial endeavors, pipelines serve not only as transportation methods but also play an...

View more

Tekla Structures is a leading Building Information Modeling (BIM) software widely used in the field of steel structure design. It provides engineers and designers with powerful tools to create...

View more

Pressure equipment is essential in a range of industries such as chemical, oil and gas, power generation, food and beverage, pharmaceuticals, and others. These vessels are crafted to handle,...

View more

Green industrial environment is becoming an inevitable trend for businesses to achieve sustainable development amid the increasing climate change and environmental pollution. This article will explore the idea of...

View more

Material waste in production presents a significant challenge for many businesses. It not only elevates production costs and diminishes profits but also impacts product quality and the competitive edge...

View more

In the age of Industry 4.0, manufacturing is crucial for boosting the economic growth. Everything from basic everyday items to advanced machinery stems from the this phase. In the...

View more

In addition to economic advantages, manufacturing activities carry inherent risks of environmental pollution, which can adversely affect public health and impede social progress. Thus, it is imperative for businesses...

View more

The manufacturing sector has experienced a remarkable transformation in recent years, driven by the extensive integration of modern technology. Transitioning from conventional workshops with manual machinery, the industry is...

View more

Steel structures, the robust backbone of countless contemporary edifices, are vital in safeguarding the safety and sustainability of our built environment. This article will guide you in answering that...

View more

We will contact you upon receipt of the information