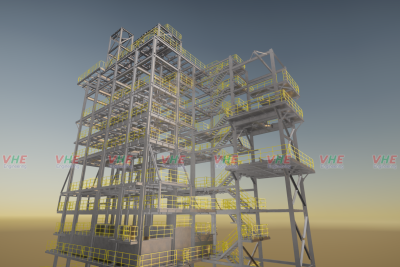

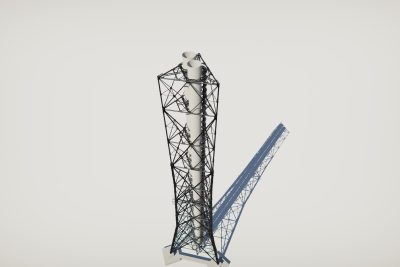

Steel: Transforming Raw Materials into Magnificent Constructions

Steel has historically symbolized the evolution of the modern construction sector. Its exceptional characteristics such as durability, high load-bearing capacity, and flexibility play a vital role in constructing both...

View more