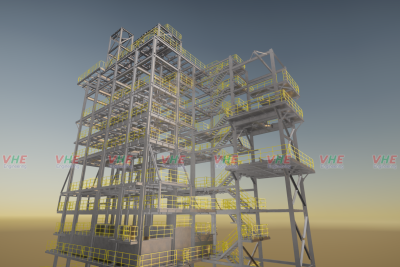

Flare System: Structure and Operating Principle.

Flare system holds a pivotal position within the manufacturing industry. Delve into an in-depth exploration of its structure and operating principles in VHE‘s article. I. Definition: In mining rigs,...

View more